CircuitWorks Overcoat Pens

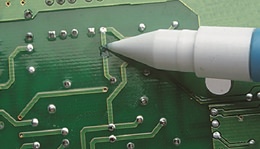

Pen dispenser for precise application of a tough protective acrylic conformal coating

CircuitWorks Overcoat Pen is ideal for protecting and insulating circuit board traces, components, and other delicate electronics. This highly effective acrylic conformal coating provides excellent protection against shorts, moisture, abrasion, fungus, and other environmental hazards. Allows for easy repair of solder mask in prototype, manufacture and repair of circuit boards.

Features & Benefits

- Simple to use, single component system

- Hard, durable coating

- High dielectric strength helps prevent electrical discharge

- Dries quickly at room temperature

- Protects against moisture and abrasion damage

- Meets requirements of MIL-I-46058C and IPC-CC-830A

Applications

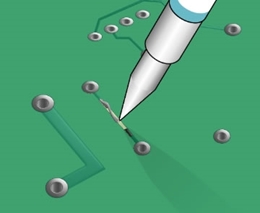

- Insulates and protects conductive pen traces

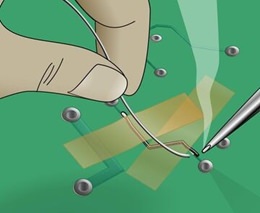

- Repairs permanent solder mask

- Prevents shorting and arcing

| TDS | |

| REGS | |

| SDS | |

| Categories |

| Specifications |

IPC-CC-830A, MIL-I-46058C, Type AR ANSI/IPC J STD-001, IPC-7711 |

|---|---|

| Shelf Life | 2 yrs. |

| Shipping Name | Consumer Commodity ORM-D |