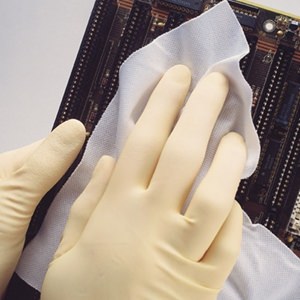

Coventry Poly-Wipes

Laundered polyester cleanroom wipes offer extra level of protection for critical applications

Coventry™ cleanroom laundered polyester wipes offer an extra level of protection for critical applications. Our Poly-wipes™ are made from 100% continuous filament polyester – the standard in cleanroom wipes – minimizing particle generation. Poly-wipes™ are laundered in our Class 10 (ISO Class 4) cleanroom, and are available with our exclusive heat-cut edge sealing process (HC).

Features & Benefits

- Excellent solvent and acid resistance

- Monofilament "no-run" construction does not generate loose fibers

- Excellent durability for cleaning rough, abrasive, or irregular surfaces

- Low ionic, nonvolatile residue and particle contamination

- Good absorbency

- Available in heavy or light weight styles

- Processed and packaged in a Class 10 cleanroom

Applications

- Semiconductor Wafer Fabs

- Aerospace Production Areas

- Disk Drives Production Areas

- Pharmaceutical / Biotechnical Production Areas

- General Cleanroom Cleaning

- Clean and polish critical surfaces both metal and non-metal

| TDS | |

| REGS | |

| Categories |

| Shelf Life | 5 yrs. |

|---|