25

Request a Sample

Your Sample Request

Konform® SR Silicone Conformal Coating

*=required field

TDS

REGS

SDS

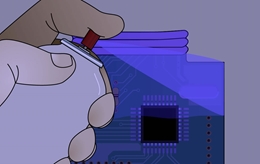

Konform® SR Silicone Conformal Coating

UL-certified silicone conformal coating for maximum flexibility and protection from extreme temperatures and vibration damage

Konform SR provides maximum flexibility for extreme temperatures. This transparent conformal coating provides ideal protection for both rigid and flexible printed circuit boards. Cured coatings are hydrolytically stable and retain their physical electrical properties after high temperature and humidity exposure. Konform SR will not stress delicate circuit components.

Konform SR is available in three different viscosities to match your application process:

- Standard viscosity - 40± 5 cps

- Medium viscosity - 60± 5 cps

- High viscosity - 120± 5 cps

Features & Benefits

- Engineered for applications where flexibility and high temperature resistance are required

- Silicone coating stable from -85°F/-64°C to 390°F/199°C

- High dielectric strength of 1100 volts/mil

- Easily removed with Electro-Wash® Two Step or CircuitWorks® Conformal Coating Remover Pen

- Passes the laboratory tests of MIL-I-46058C. However, it is not qualified on QPL-46058.

- Compliant to IPC-CC-830A

- RoHS Compliant

- UL Recognized, File E76307

- UL 94 V-0

- Contains a UV indicator for Quality Control inspection using medium intensity light at 265-335 nm

Applications

- Extends component life by protecting against adverse environments

- Good insulation properties, excellent flexibility

- Resists moisture, salt, fungus, corrosive vapors, and severe environments

- Engineered to withstand heat generated by electronic circuitry as well as climatic temperatures

| Specifications | IPC-CC-830A,UL Recognized |

|---|---|

| NSN | 5970-01-417-4152 |

| Shelf Life | 1 yr |

Articles

Flexible Electronics Soldering Challenges: CircuitWorks Conductive Epoxy to The Rescue

This article discusses the potential of hybrid printed electronics (particularly as wearable gadgets) and provides some examples. We then compare various methods of mounting electronic components on flexible substrates and highlight Chemtronics’ products which aid electronics manufacturers to addres...

Read This Post

HOW-TO: Conformal Coating Application Using Aerosol Spray

Step-by-step instructions on how to properly apply aerosol coatings without common defects.

Read This Post

Webinar: Optimizing Selective Spray Conformal Coating for Maximum Output

This is a overview of PCBA conformal coating application with selective spray systems and tips for optimizing equipment settings and chemistry selection for the best (and most profitable) possible performance. Presented by industry experts Pierce Pillon, Senior Field Engineer of Techspray, and Jon U...

Read This Post

Conformal Coating Defects: When Things Go Horribly Wrong

Even small failures can cause conformal coating defects and your line to shut down. This video shows how to diagnose, solve, and prevent defects in your process

Read This Post

The Ultimate Guide to Conformal Coating

Conformal coating is engineered to protect circuit boards, components, and other electronic devices from moisture, thermal shock, static, vibration, and contamination. These coatings ‘conform’ to the irregular landscape of the PCB providing increased dielectric resistance, operational integrity, and...

Read This Post

How To Evaluate The Best Silicone Conformal Coating

Many engineers specify legacy silicone coatings as a “good enough” de facto standard, but shortages in those product lines open the opportunity to consider other materials with superior characteristics. Unfortunately, evaluating new coatings and potentially having to adjust processes to accommodate ...

Read This Post

8 Essential Tips for Conformal Coating Dip Application

If you are wondering on how to apply your conformal coating or considering the different options for your conformal coating process, take a look at this quick post covering the best practices of dip applications for coating PCBs.

Read This Post

How To Select A Conformal Coating

Related Products

You did not finish submitting your information to request a sample