Products for Controlled Environment & Cleanroom

Coventry™, a brand of ITW Chemtronics®, is known globally for solving the most critical precision cleaning challenges. Coventry has a wide variety of cleanroom swabs and wipes to meet your most demanding applications. The wrapped swab, uniquely designed with no seams or edges, prevents scratching of delicate surfaces. Also included in the product line are sealed fabric, sealed foam, and static control. You’re sure to find a swab from Coventry that meets your particular need.

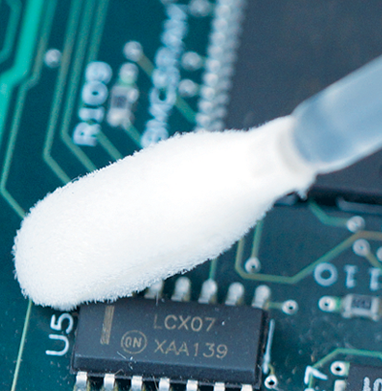

Cleanroom Swabs

Coventry™ cleanroom swabs and applicators keep contamination out of your process, improve yield, and perform consistently, shipment to shipment. To manufacture a Coventry swab, we start with engineered clean materials. Polyester swab and wipe components are laundered first in our Class 10 (ISO Class 4) cleanroom.

View ProductsCleanroom Wipes

Coventry™ cleanroom wipes keep contamination out of your process, improve yield, and perform consistently, shipment to shipment. To manufacture a Coventry swab, we start with engineered clean materials. Polyester materials are laundered first in our Class 10 (ISO Class 4) cleanroom.

View ProductsHigh Purity Solvents

Coventry™ solvent cleaners, swelling agents and carrier fluids are formulated and manufactured to exacting specification to provide unparalleled performance.

View ProductsAsk us how we can improve your process.