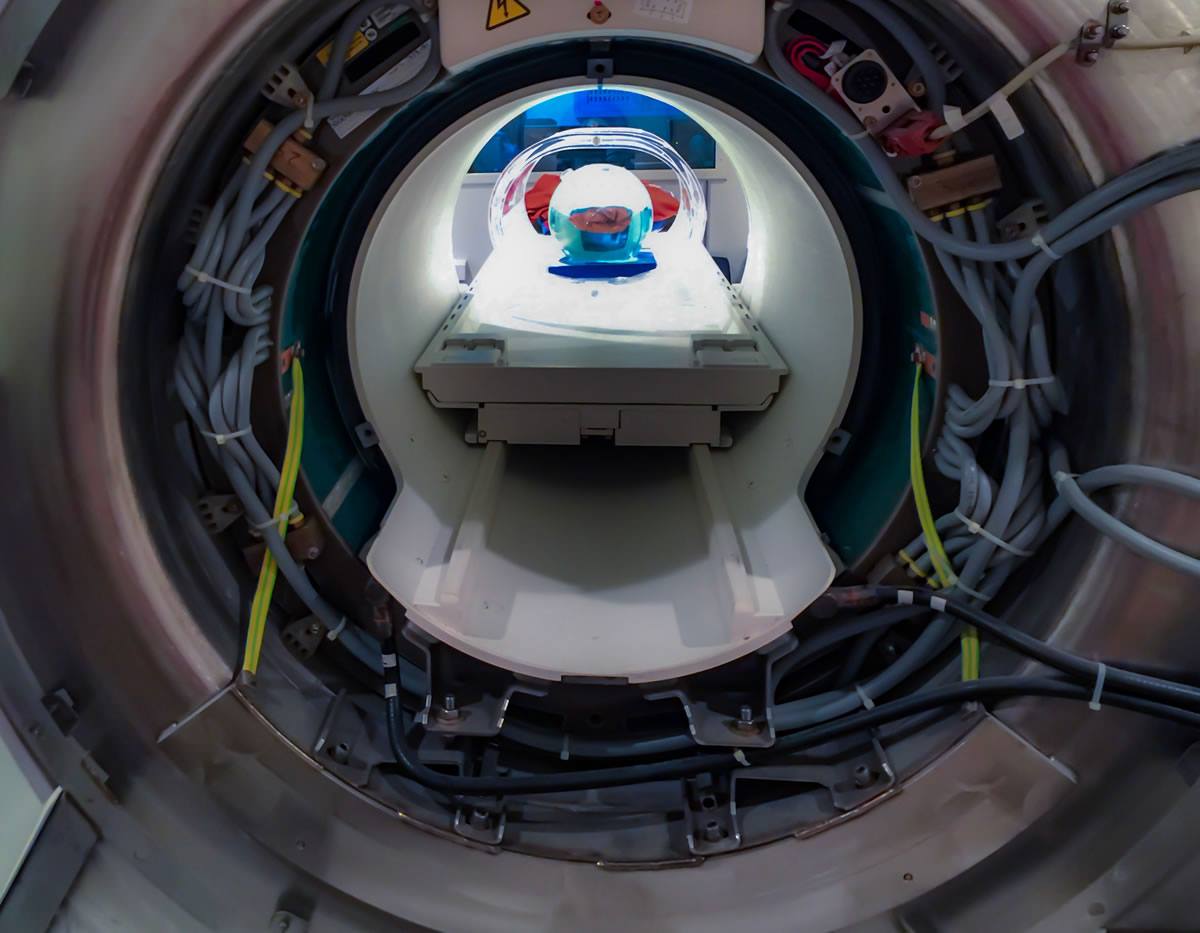

When it comes to scanning and diagnosis in medicine, few types of equipment can match the effectiveness of the MRI scanner. An MRI scanner is a medical imaging device capable of detecting anomalies and defects in the body and joints and can evaluate infertility in women. It uses a combination of magnetic and radio wave properties which in concert coordinate the clarity of the resultant images.

Like most advanced devices, an MRI relies on maintenance, cleaning, and inspection for optimal performance. Chemtronics provides several products ideal for cleaning the electronics, interfaces, systems and crevices during both operation and in the requisite servicing. Understanding how an MRI operates will identify those systems most in need of cleaning and maintenance.

How Does MRI Equipment Work?

To understand an MRI (Magnetic resonance imaging), one must consider the magnetic properties of the human body. The body is comprised of about 70% water which means an abundance of hydrogen protons. These hydrogen protons are polar but the poles are generally randomly oriented. When a strong magnetic field from the MRI scanner is presented, the axes of the hydrogen protons align along the axes of the MRI magnets. Then radiofrequency waves provide additional energy to the magnetic field, deflecting the magnetic vector—this creates resonance.

The Image forms when the radio frequency emitter turns off, and the intensity of radiowaves are plotted on a greyscale, resulting in an energy emission map as the magnetic vector gradually returns to its original vector state. As with many other medical imaging equipment, the image obtained is greyscaled and cross-sectional to give the most detail.

Why Is MRI Maintenance Important?

The Magnetic resonance imaging (MRI) scanner relies on magnetism and radiofrequency. Regular maintenance ensures no long-term defects or associated problems from its usage. Both preventive and corrective maintenance play a crucial role. Technicians and operators are required to follow the terms of use and utilize periodic inspection and testing. Some of the defects associated with an MRI scanner are:

- Blurry images may result from defective gradient coils, which can occur from extended neglect and lack of proper maintenance.

- Excessive vibrations, similar to blurry images, also tend to originate from defective gradient coils.

- Low helium levels are a common defect observed in MRI machines, which can be dangerous because helium plays an essential role in internal cooling.

- Power outages are a common problem resulting in a lack of consistent service delivery. They can also lead to defects in the cold head and inaccuracy in the calibration of the gradient coils.

- MRI scanners work within a very narrow temperature range, if the defects cause poor cooling the MRI will shut down and fail to operate.

Routine Maintenance To Extend the Service Life of MRI Equipment

The main objective behind maintenance is to reduce the cost of replacement, inefficiency costs from having an inoperable machine, and to prevent accidents. The levels of supervision may be corrective or preventive maintenance. In preventive maintenance, a technician ensures the internal components are regularly inspected and maintained, and performance tested. Inspections require regular cleaning. Some areas of the MRI scanner that require constant inspection or enhanced add-ons include:

- The alignment of the gradient coils to correct any anomaly which could damage the photos.

- Identifying and correcting low helium levels. Low helium levels cause poor cooling and proper temperature regulation, which cause inefficient operation. Alternatively, remote diagnostics can be installed to detect and refill helium levels automatically.

- Power outages that lead to loss of crucial data can be preventable through power backup systems, the most effective being a UPS (Uninterrupted power supply).

Periodic cleaning of surfaces with a disinfectant are also crucial in the operation of the MRI scanner.

The following section addresses the mechanism employed by each of the major sections in their operation and how they can be maintained for long-term reliability and greater efficiency in service delivery.

Magnets

The magnets are the most important part of the MRI as they align the poles of the hydrogen atoms that can then be mapped and imaged.

To operate efficiently, the magnets need to be at the right temperature and, for that reason, they are cooled using a cryogenic (helium). One major defect that can occur is a condition called “quench.” This is an increase in the temperature of the magnets, which results in a direct decrease in the level of conductivity. To avoid this from happening, the helium content is analyzed to ensure the correct quantity and that there is no contamination.

Cold Head

The cold head is an important part of the MRI for cooling. It turns the gaseous helium into liquid and prevents it from entirely burning off. Without the cold head, the helium would easily get lost, and the magnets would lose their superconducting properties.

Some major defects associated with the cold head include the drop in the recondensing margin. This is a result of its nature to gradually lose efficiency at a rate of 10% per year; the best approach in this scenario is the replacement of the cold head. Almost all maintenance programs recommend replacement since it's much cheaper and easier in the long run. The maintenance program entails carrying out routine oil tests. The cold head’s absorber is also replaced on a regular basis to ensure there is no contamination.

Gradient Coils

These play the role of creating a secondary magnetic field; the aim is to generate spatial encoding by predictably distorting the magnetic field. The coils play a vital role in the scan process but are susceptible to defects. Common causes of failure are a result of component fatigue, improper use, and rough handling.

There are guidelines for proper handling and regular cleaning. Standard service agreements come with specific provisions of labor and repair costs when it comes to both the gradient coil and radiofrequency maintenance.

RF Coils

The radio frequency (RF) coils are used as receivers and transmitters in the MRI scanner. As receivers, their role is to detect the signals from the magnets, and as transmitters, they generate either the rotating or oscillating magnetic fields.

The maintenance process entails proper handling of the equipment and regular cleaning. It also requires checking the radio frequency power output and ensuring it is set to the appropriate level. One common defect stems from forcing the connectors to the wrong receptacle. During the repair process, it is crucial to ensure there is proper protection from electrostatic discharge, and this will help protect the internal components from damage as well as shield the repair technician.

Electronic Support System

The electronic support system is responsible for the processing and the transmission of the data gathered. Some common defects of the display system often involve blurry images which stem from irregular spatial and temporal uniformity within the MRI scanners.

Repair and maintenance of the electronic system are handled by qualified engineers, either licensed service providers or the original equipment manufacturer (OEM).

Computer System

The computer systems in the MRI system are designed to execute important roles in the operations of the scanner. These include control of the gradient pulses, collection, and processing of data needed for the images. Post-processing is what gives us the final images.

An important practice in ensuring the operations of the devices is by having a regulated power supply through UPS (Uninterrupted Power Supply) and regular updates to the software.

Chemtronics Cleaners and Coventry Wipes & Swabs for MRI Maintenance

Chemtronics offers specialty cleaning products engineered to be effective and safe for the equipment, personnel and the overall environment.

- High precision solvent cleaners, either in aerosol or liquid form, are engineered to be safe on sensitive electronics and surfaces, but strong enough to remove flux, oils and other contamination.

- Lint-free wipes are strong and absorbent, and without risk of contamination from the wipe material itself.

- ESD-safe swabs are available in a wide variety of shapes and materials to clean inside the many tight crevices of MRI equipment. The specialized handles prevent static build-up that can damage sensitive electronics

For more information, contact your Coventry cleanroom application specialist at 678-928-6534 or [email protected].

References

Gilmore Health News. (2021). “Why MRI Machines Need to Be Maintained Continuously?”. https://www.gilmorehealth.com/why-mri-machines-need-to-be-maintained-continuously/

Berger, Abi. “Magnetic resonance imaging.” BMJ (Clinical research ed.) vol. 324,7328 (2002): 35. doi:10.1136/bmj.324.7328.35

https://pubmed.ncbi.nlm.nih.gov/11777806/

Ask A Technical Question

Stay up-to-date on Chemtronics news, products, videos & more.