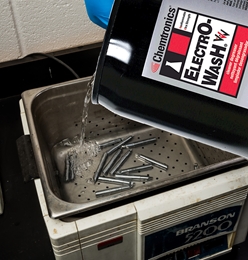

Electro-Wash Tri-V Degreaser

Extra-strength, nonflammable electronics cleaner degreaser for replacing n-propyl bromide

The Ultimate n-Propyl (nPB) Replacement

Electro-Wash Tri-V Precision Cleaner is a nonflammable cleaner that quickly removes flux, grease, oils, dirt, dust, and other contaminants from electronic components and assemblies. It removes all types of oil and grease while evaporating quickly and leaving no residues. Tri-V nPB replacement chemistry is an innovative chemistry that does not contain n-propyl bromide, TCE, hazardous air pollutants or ozone depleting compounds.

Removes oils, greases, silicones, refrigerant oils, fluxes, adhesives and other common industrial contaminants. Used for cleaning medical instruments, implants and other devices including orthopedic implants, monitoring devices, oxygen and gas lines. This solvent can be used as a carrier fluid like for silicone-based lubricant coatings.

CLICK HERE FOR CLEANER DEGREASER SELECTION GUIDE

Features & Benefits

- Powerful cleaning agent to remove flux, oils, dirt, grease, dust, and other contaminants, one cleaner for electronics cleaning

- Nonflammable, can be used on energized equipment

- Penetrates to clean hard to reach areas

- Evaporates quickly and leaves no residues, minimizes down time

- Does not contain n-propyl bromide, trichloroethylene, or perchloroethylene

- Stabilized for metals such as aluminum, magnesium, titanium, and brass

- Noncorrosive, safe for sensitive metals

- NSF Registered - Nonfood Compounds / Code K1 and K2

Applications

- Printed circuit boards

- Relays and switches

- Transformers

- Electro-mechanical devices

- Electric motors and generators

- Electronic controllers

- Circuit breakers

- Cleaning medical instruments like monitoring devices, oxygen and gas lines

- Clean orthopedic implants

- Carrier fluid like for silicone-based lubricant coatings

| TDS | |

| REGS | |

| SDS | |

| Categories |

Vapor Degreaser Setting Guidelines

- Boiling point – 118°F / 48°C

- Boil sump temp set – 127°F / 53°C

- High solvent temp set – 136°F / 58°C

- Refrigerant high temp set – 109°F / 43°C