A hematology analyzer or hemocytometer is one of the machines used inside a clinical laboratory. It rapidly analyzes whole blood specimens for the complete blood counts and differential blood counts. Red blood cells, white blood cells, hemoglobin, and platelet counts are also directly measured.

A hematology analyzer is used for the early detection of any abnormalities in human blood. The machine follows the “Coulter Principle” on counting blood cells. Blood counts are very useful for the early diagnosis of possible infections and abnormalities such as Anemia, Leukemia, Hemophilia, and Lymphoma.

Here are some tips on how to acquire reliable results for a dependable diagnosis.

How Does a Hematology Analyzer work?

- A Medical Technologist extracts samples from the patient.

- The sample will be fed to the aspiration needle to start the testing.

- The sampling needle will aspirate the whole blood and dispense it in the chambers.

- The aspiration syringe will aspirate diluent, lyse, and dispense into the chambers.

- The reaction will happen inside the chambers wherein the blood cells are divided into parts.

- The machine will start counting the blood cells.

- After testing, the machine will automatically perform probe cleaning, chamber washing, and waste draining.

The normal maintenance routine for a Hematology Analyzer has daily, weekly, monthly, and semi-annual processes.

Routine Hematology Analyzer Maintenance

Small dust particles may cause a deviation from normal results. Regular surface cleaning is a must.

- Prepare Coventry cleanroom wipes to clean the overall surface of the machine and its surroundings. (Note: Cleanroom wipes are not reusable. Reuse may cause future contamination.)

- Check the liquid level of the waste container, lyse bottle, and the diluent. If the waste container is full, dispose of the waste and connect a new container.

Daily Hematology Analyzer Maintenance

- Prepare Chempad Alcohol wipes to clean the aspiration needle. (Note: Chempad Alcohol wipes are not reusable. Do not reuse to avoid future contamination.)

- Run blank testing to check whether the machine has a carryover.

- Everyday Quality control is a must. Ensure the machine is properly calibrated.

- Shut the machine down properly and clean the aspiration needle using Chempad Alcohol wipes. (Note: Chempad Alcohol wipes are not reusable. Do not reuse to avoid future contamination.)

Aspiration probe

Note: Some machines are programmed for daily automatic cleaning. This may require fresh cleaning solution every eight hours or after a certain number of tests.

Weekly Hematology Analyzer Maintenance

Machines have built-in cleaning functions but there are times that these functions cannot clean the machine thoroughly.

- Prepare the cleaning solution prescribed by the manufacturer to start the cleaning function.

- Aspirate the cleaning solution to soak the chambers to ensure that blood stains will be eliminated.

- Perform the built-in flushing and washing function of the machine.

- Perform zapping to eliminate possible blockage on the aperture.

Monthly Hematology Analyzer Maintenance

More intensive cleaning is required on a monthly basis.

- Turn off the power supply and remove the power line.

- Clean the computer set (workstation) using Chempad alcohol wipes and Chemswab alcohol wipes to clean the workstation.

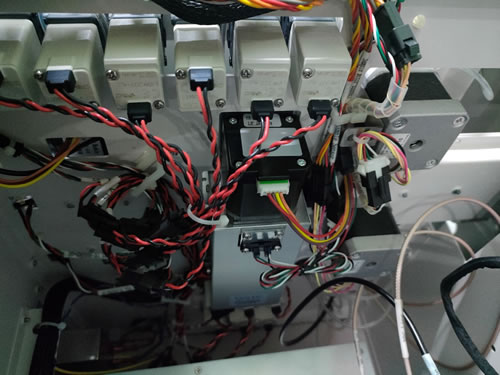

- Open the doors of the machine and access the electronic components of the machine. Use an Aerosol duster on circuit boards to eliminate dust and dirt.

Electronic components

- After the cleaning process, check the cables to ensure they aren’t loose, and proceed to test the machine.

Semi-Annual Hematology Analyzer Preventive Maintenance

The semi-annual maintenance process should be performed by the Engineer, as it requires technical knowledge.

- Turn off the power supply and unplug the device.

- Remove the communication cable and the waste sensor.

- Disassemble the tubing for the diluent, lyse, and waste.

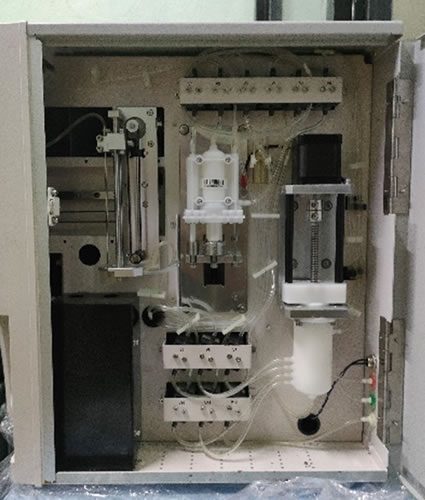

Connection port for diluent, lyse, waste, and waste sensor

- Clean the outside of the tubing using Chemswab Alcohol Wipes.

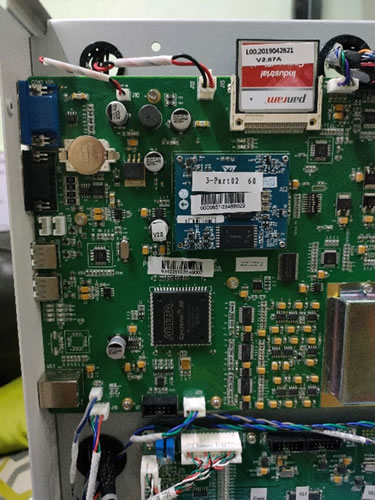

- Open all the covers of the machine to access the liquid system and the electronic system (Microcontroller).

Liquid system

Microcontroller

- Use an Aerosol duster on circuit boards to eliminate dust.

- Use Chemtronic swabs to remove dirt.

- Using ESD Static control swabs, clean the connectors of the RBC and WBC sensor.

RBC and WBC connectors

- Open the liquid system and wipe out dust particles.

- Dismantle the valves and clean the outside appearance.

- Disassemble the valves with visible crystallization and clean using Chempad alcohol wipes and Chemswab alcohol wipes.

Valves

Example of crystallized part

- Open the WBC and RBC Chamber. Clean the chambers using Chemtronic swabs to remove blood stains.

Chamber

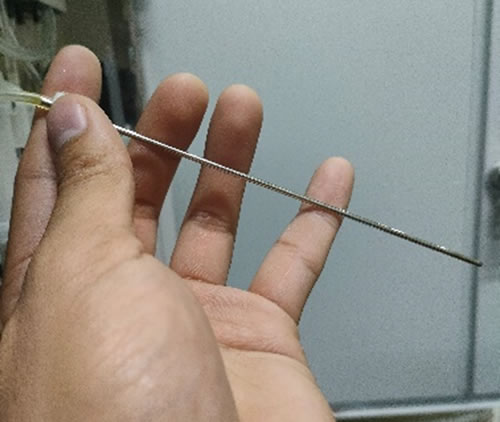

- Dismantle the aspiration needle and clean it. Prepare a thin wire to clear any possible blockage in the aspiration needle.

- Re-install dismantled parts and re-install the tubing.

- Power on the machine and check for any sensor alerts.

- Go to the maintenance menu to perform flushing and cleaning functions.

- Cauterize the aperture to remove the blockage using the zap function.

- Run blank testing and verify the results.

- Run QC to check whether the machine is calibrated.

Diagnostic machines are crucial to ensure patients have accurate diagnoses and treatments to maintain health and to assess proper treatments. You can only obtain reliable results by performing proper maintenance with the help of high-quality products.

Ask A Technical Question

Stay up-to-date on Chemtronics news, products, videos & more.