Tacky fluxes are commonly used in the electronics assembly industry for a variety of applications. These fluxes generally have honey-like consistency and can be used for ball attach applications, BGA re-balling and hand soldering applications.

CircuitWorks® No-Clean Tacky Flux (part #CW8500) is a mildly activated rosin (RMA) no-clean tacky flux. Its formulation includes a unique rosin/resin blend coupled with a proprietary blend of activators and stabilizers, providing significantly increased shelf life and long-term product stability. This results in a post solder residue that is stable and can be left on a board without cleaning.

Tacky Flux Performance Characteristics

CircuitWorks No-Clean Tacky Flux offers a combination of a stable platform with robust activity. In this regard CircuitWorks No-Clean Tacky Flux is ideally positioned between the more traditional RMA paste fluxes and the synthetic low residue-tacky fluxes. Typical RMA fluxes have strong activity but lack stability and consistency, whereas synthetic low-residue tacky fluxes are stable in their characteristics, but only sufficiently active for a limited range of soldering parameters. CircuitWorks No-Clean Tacky Flux can be used in a wide range of soldering applications with predictable results.

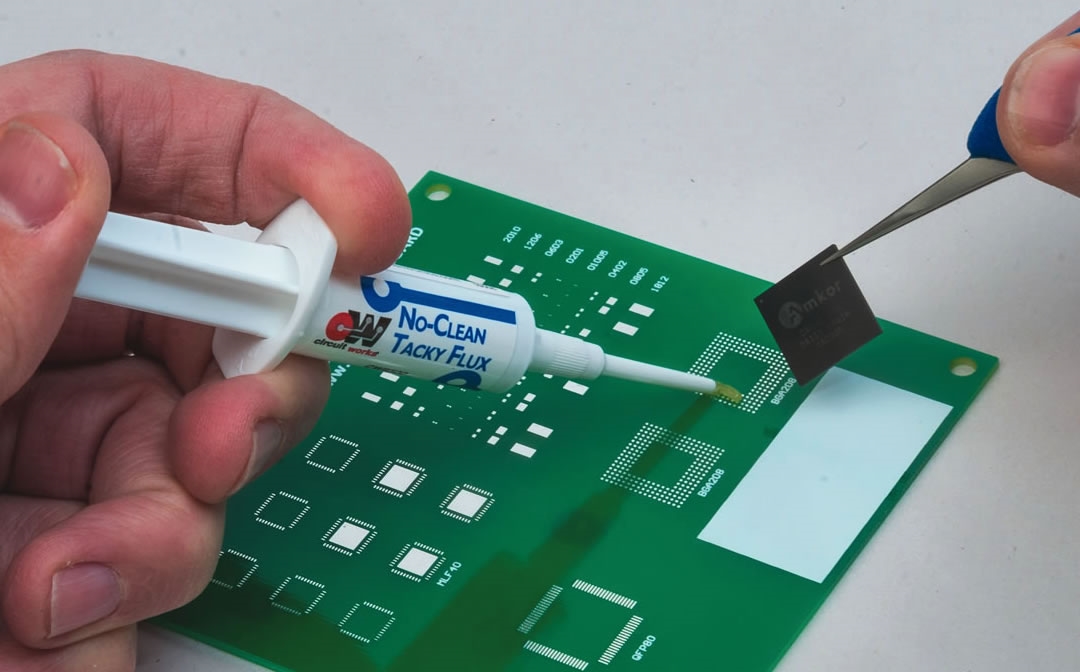

CircuitWorks No-Clean Tacky Flux can be used for the following applications: BGA ball attachment and detachment; repair and rework of printed circuit board (PCB) components; and soldering of specialty components that cannot be attached in standard SMT reflow of PTH wave solder applications. The flux can be screen printed or dispersed via manual dispenser (syringe), and it can be manually spread to cover a desired area for soldering.

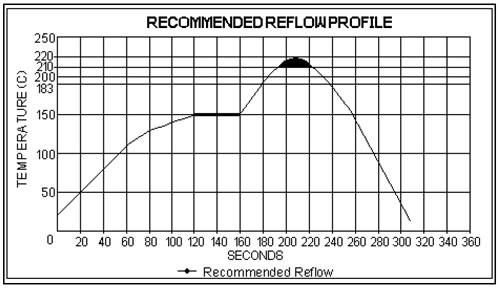

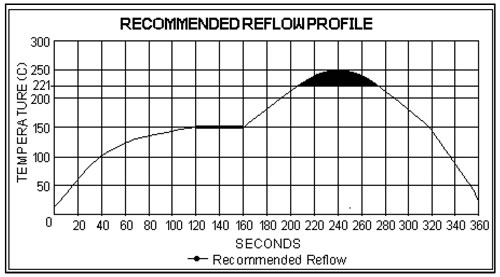

Typical soldering temperature range for the CircuitWorks No-Clean Tacky Flux is 480-650°F/250-343°C, though depending on the application, the flux can perform at higher temperatures than these. The heat source can be a soldering iron, a reflow oven, or other reflow tools.

Recommended reflow profile: 63Sn/37Pb

Reflow profile for lead-free / SAC305

Flux Residues: To Clean or Not to Clean

CircuitWorks No-Clean Tacky Flux leaves a brown, translucent residue. The flux contains neither halides nor halogens rendering the post solder residue stable. The residue therefore does not need to be removed after soldering, but using Flux-Off No Clean Plus to remove residues where cleaning applications are required (such as coating application, contract obligations, etc) is recommended. Post solder residues are pin testable.

For more information, contact your Chemtronics application specialist at 678-928-6534 or [email protected].

Ask A Technical Question

Stay up-to-date on Chemtronics news, products, videos & more.