A common method of repairing a broken trace is to solder on a jumper, which is basically a wire bypass around the broken trace. This can be time-consuming and visually unappealing. Chemtronics offers CircuitWorks Conductive Pens which contain a highly conductive material like silver or nickel suspended in a liquid polymer. These pens allow you to literally redraw the trace.

The following are steps to quickly and effectively repair a trace with a conductive pen.

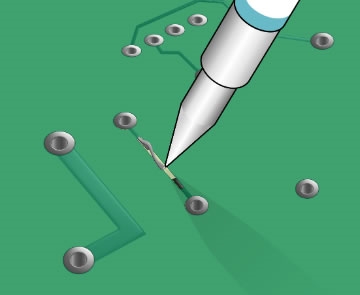

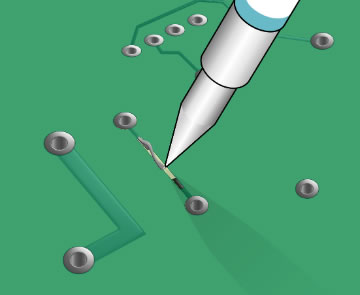

Step 1: Scrape away resist from repair areas.

|

Scrape away resist.

|

The damaged trace should be cut away and removed using a cutting tool, being careful not to damage any surrounding traces, components and contacts. Whenever possible, this repair should be made at least three millimeters away from contacts that will later be soldered in order to minimize the chance of reflowing the repair. Before pulling off the damaged trace, double-check that your cut is complete. Otherwise you risk lifting up the remaining trace and/or contact. Before you can add a jumper, the conductive surfaces must be exposed at the point of the break. You can use the cutting tool to carefully scrape away at least 3mm length of the overcoat material. A rotary tool grinding bit, held in your hand, is a good tool to gently scrape away resist in a controlled way. Make sure to scrape lightly to avoid damaging the conductive material of the trace underneath. Use an alcohol cleaning wipe, solvent cleaning pen, or some other method to remove overcoat particulates and other residues from the repair area. |

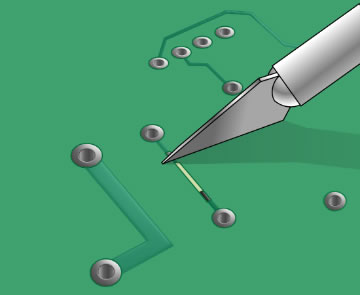

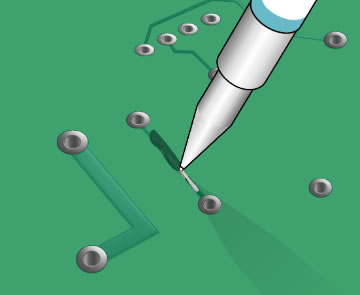

Step 2: Clean surface.

|

Clean off resist particulates. |

Use an alcohol cleaning wipe, solvent cleaning pen, or some other method to remove overcoat particulates and other residues from the repair area. |

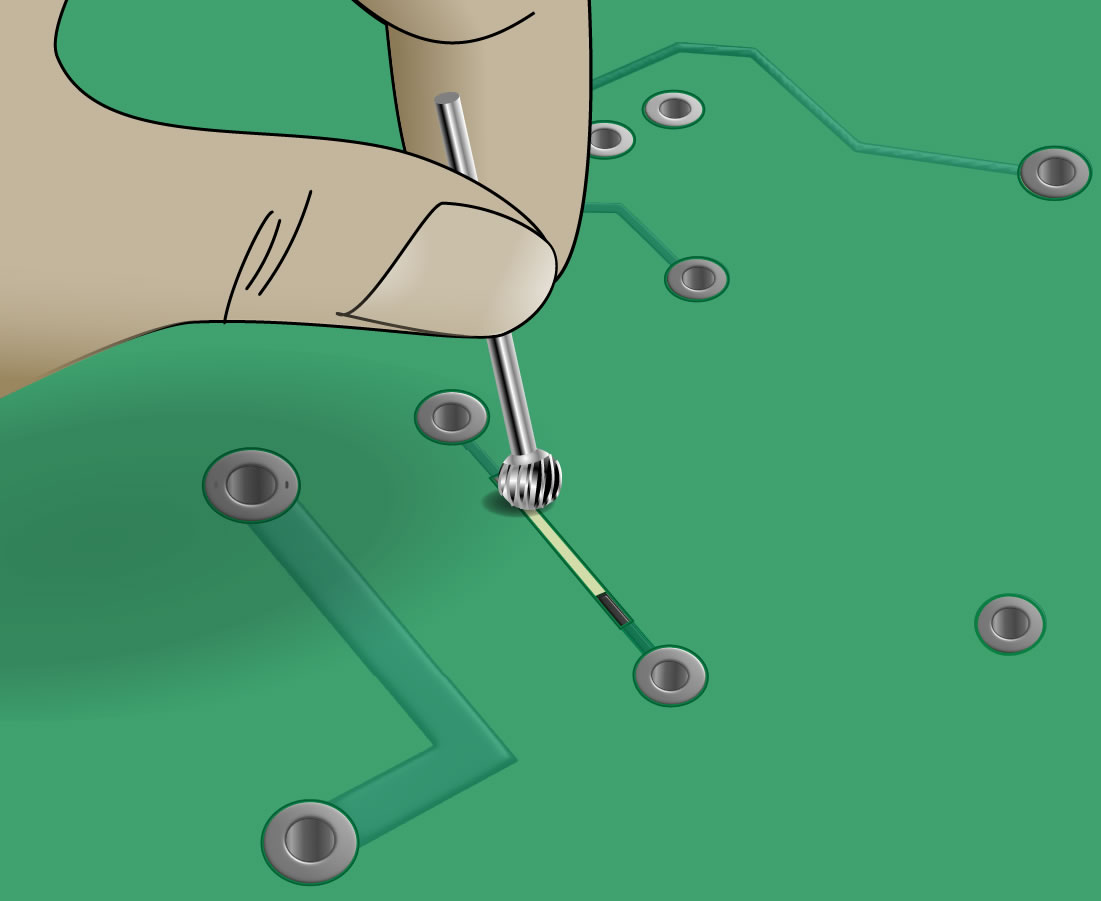

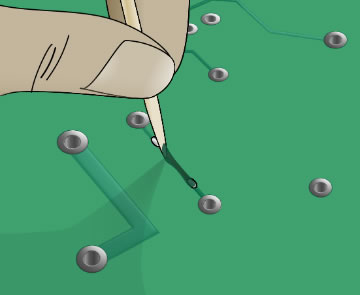

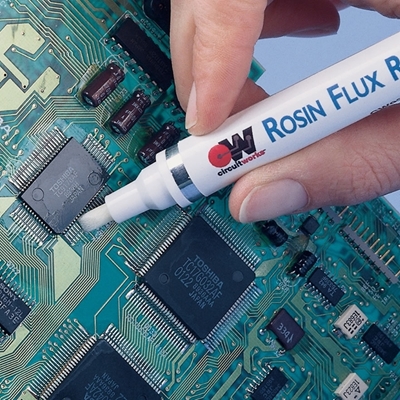

Step 3: Draw trace with conductive ink.

|

Draw trace. |

Vigorously shake the conductive pen until you hear the internal ball rattle. Press the pen tip at the break area and squeeze the pen barrel to dispense the conductive ink. Allow the conductive ink at least one hour to cure before repairing the overcoat. |

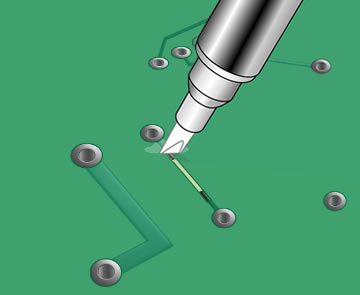

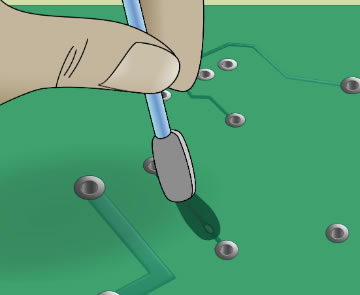

Step 4: Apply overcoat over trace repair.

|

Option 1

Apply overcoat to repair area. Option 2

Apply overcoat to repair area.

Spread and texture overcoat. |

Option 1: Overcoat Pen Use a CircuitWorks Overcoat Pen to repair the resist area in the break area. Overcoat pens come in a variety of colors to match the color of the PCB. Press down the pen tip and squeeze the barrel to dispense the overcoat material. Option 2: Overcoat Epoxy Mix the overcoat epoxy according to the manufacturer 's instructions. Apply the epoxy over the trace with a pick. A lint free foam swab can be used as needed to thin and spread the epoxy over the sides of trace. Polyamide tape may be used to mask areas from the epoxy. Alternatively, an overcoat pen can be used to cover and protect the reapired trace as long as the coating will not be exposed to extreme soldering temeratures. The will enable a faster application and cure more quickly. Cure the epoxy or overcoat according to the manufacturer’s instructions. Do not cure at a heat which components on the board cannot tolerate, however. |

Tools & Materials

- Cleaner like flux remover pen or alcohol pad

- Epoxy overcoat or overcoat pen

- Conductive pen or conductive paint

- Knife or scraping tool

Ask A Technical Question

Stay up-to-date on Chemtronics news, products, videos & more.