CASE STUDY: Fiber Optic Connector Failures at a Waste Incineration Plant

By Kevin Pawlowski, Marketing Communications Manager

At Chemtronics, we offer cleaning solutions for the messiest problems, and it doesn’t get messier than a waste incineration facility.

You may not realize this, but when you send a message through our website, it isn’t filtered by some robot or sent away to some faraway land for processing. It drops into my inbox. A request came through for information on fiber optic cleaning kits for a nearby waste incineration plant. Since this was local and I’m always up for interesting field work, I gave them a call to understand better and offer to visit.

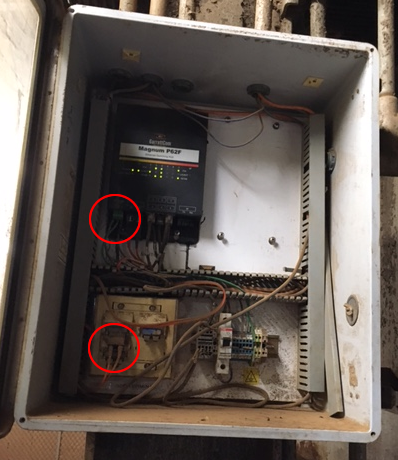

There are converter boxes from copper to fiber optics for controllers around the incinerators. This is where they incinerate solid waste from the surrounding area – yes, that kind of waste. They have been getting enough failures that they were considering replacing the controllers. Because it is such a dirty application (an understatement), they thought it may be the 2.5mm connectors. The ferrules are accessible, but the recessed connectors are hard to reach, making cleaning a challenge.

Fig 1 – Incineration plant Fig 2 – Mr. “Dirty Jobs” himself

Field Visit and Diagnosis of Connectivity Issues

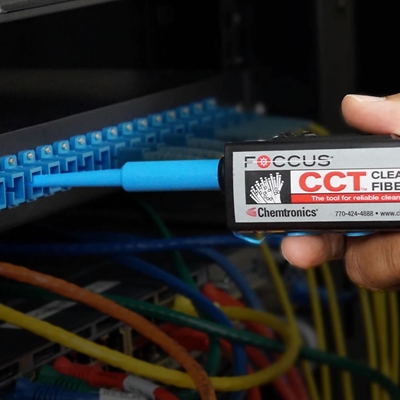

I visited the incineration plant with samples FOCCUS™ fiber optic cleaning pens, swabs, CCT™ tools, QbE cleaning platforms – the works. After a demonstration, I was suited up for an in-person look at what was going on.

They wanted to set up a cleaning process for very dirty connectors in the incineration plant. The solid waste from wastewater is sent through a giant centrifuge, so as much liquid as possible is removed. Remaining solid waste is sent through the top of the incinerator and works through several consecutive chambers until is it fully incinerated (i.e. turned into poop ash). Carbonized feces dust gets everywhere. Controllers that manage heat, air input, etc., are fiber, but computer network has a copper Ethernet backbone, so a fiber optic jumper goes from a converter to the controller.

They had some cleaning tools they were testing out, but were not impressed by the "dental floss" material. They were skeptical that it would clean well enough, since it looked like it was designed to clean just the fiber plane, and not the full end face. The FOCCUS™ CCT tools have a wider strip of material, so better suited to clean the entire end face.

They also tried isopropyl alcohol (IPA), the go-to standard for this type of cleaning, but it left residue. I explained how using too much cleaner can flood the connector and draw up contamination for around the ferrule. Also IPA draws in moisture from the air and leave behind halos or water spots as it dries. Click here [https://www.chemtronics.com/how-to-clean-and-how-not-to-clean-fiber-optic-connectors] for more details.

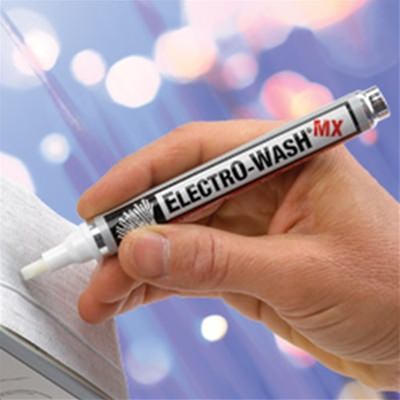

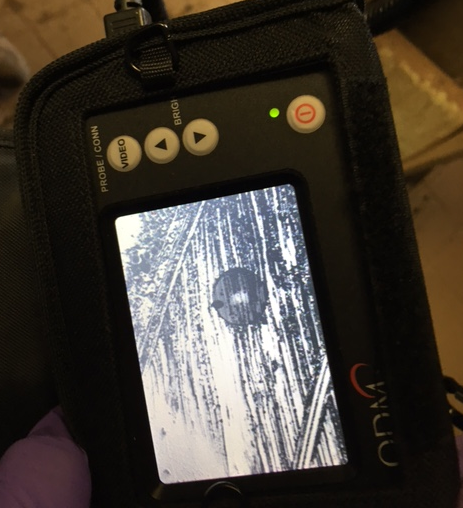

I pulled connectors and they were very dirty. Recessed connectors were not accessible with with the CCT-250. I used QbE on ferrules and 48040F 2.5mm swab on recessed connectors. I used the Combination Cleaning™ method with FW2150 FiberWash MX pen. With the swab, I used one wetted swab, and one dry swab per connector. You basically push the wet swab tip into the recessed connector until it bottoms out, give it a twist, then repeat with the dry swab for that wet-to-dry action. Click here [https://www.chemtronics.com/the-combination-cleaning-guide-for-fiber-optic-connector-cleaning] for details.

Fig 3 – Controller connection Fig 4 – Ferrule end face before Fig 5 – Ferrule end face after

(fiber connectors marked in red)

Conclusion: As expected given the work environment, the fiber connectors were getting very dirty. I recommended at least weekly cleaning using the wet-to-dry cleaning process with the FiberWash pen and a QbE for the accessible connectors, and swabs for the recessed connectors.

Fiber optic end face cleaning needs to be considered any time two fiber connectors have to come together. All it takes is a speck of dust to bring down a network or in this case, break the connection between equipment systems. You need to keep on the lookout for contamination issues whether you are in a pristine data center or in a more (ahem) crappy environment.