There is various equipment inside a medical laboratory. One common piece of equipment is the Chemistry Analyzer. A Chemistry Analyzer is a medical laboratory device used to measure the different parameters of a human body. Human serum or urine is mixed with the reagent to calculate the clinical values of the specific parameters. Lipid profiles, FBS, RBS, BUN, BUA, and liver function tests are common parameters measured by the machine.

The Chemistry Analyzer calculates parameter concentrations into numerical clinical values. These clinical values then help diagnose a patient's current condition. Either below or above the normal range of values is considered an abnormality. Research values are clinical values used to define the normal range of values in clinical chemistry.

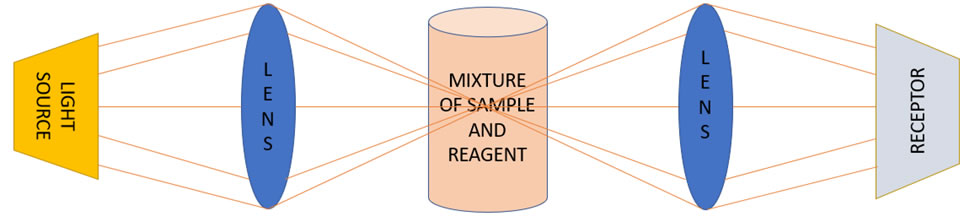

Chemistry Analyzers use the turbidimetry method in calculating the concentrations of the parameters. The turbidimetry method is explained by "the change in the intensity of the emitted light from the light source received by the receptor after passing through the lens and the sample." This could also be called simply the absorbance.

There are two types of chemistry analyzers: Semi-automated and Fully-automated. Fully-automated chemistry analyzers don't need human intervention in mixing samples or in dispensing reagents. Both machine types have an optical system and follow the same turbidimetry method in reading concentrations.

How Does a Chemical Analyzer Work?

Fig 1.1 Diagram of how a chemistry analyzer works

|

Prepare sample from the patient |

|

|

Mix reagent and sample |

|

|

Incubate based on reagent instructions |

|

|

Feed mixture into the machine for reading |

|

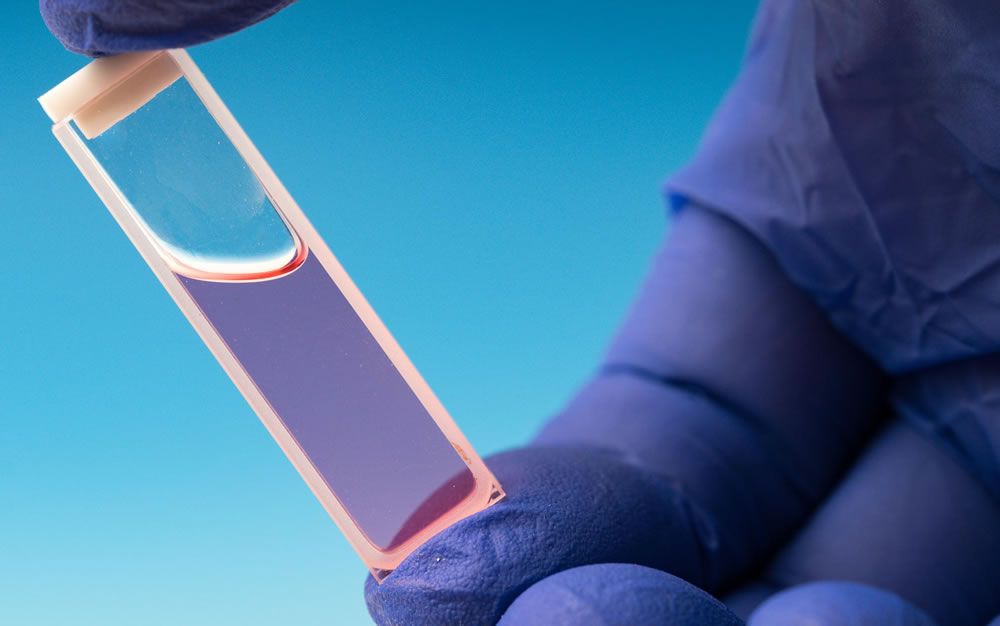

First, prepare the sample from the patient. Blood samples must be centrifuged to separate the red blood cells from the necessary serum for the sample. Then prepare a glass tube and mix the serum or urine sample with the reagent and incubate the mixture per the reagent specifications. When the incubation time is finished, feed the mixture to the machine to calculate the concentration into a reading.

How Does a Chemical Analyzer Read Absorbance?

Fig 1.2 Diagram of how a chemistry analyzer reads the absorbance

The chemistry analyzer has an optical system composed of a light source, a receptor, and lenses. The light source emits the original signal, which is reflected by the first lens, through the sample, then reflected again and thence to the receptor. The receptor measures the received light from the light source after passing through the lenses and the samples which then generates the turbidimetry measurement.

Clinical data are crucial to accurate diagnoses and life preservation, and therefore Chemical Analyzers need to be maintained to eliminate erroneous results.

How To Maintain a Chemistry Analyzer

There is a lot to consider in maintaining a Chemistry Analyzer as small dust particles, dirt, oil, or fingerprints within the system can lead to inaccurate results. Here’s some elements of the machines that need cleaning or regular attention.

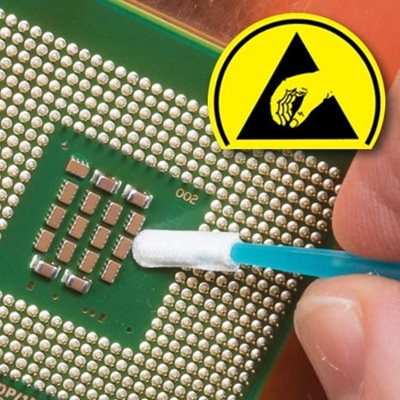

Cleaning the Electronic Boards and Internal Components

Step 1: Dismantle the cover of the machine. It will help us access the electronic board, exhaust fan, and other parts inside the machine.

Step 2: Clean the electronic circuit boards using the Chemtronics Duster and Chemtronics dry wipes to ensure 100% cleanliness and eliminate dirt or dust particles. Do not reuse wipes as they can cross-contaminate or spread soil into more sensitive components.

Cleaning the Optical System

Step 1: Dismantle the Optical system and the halogen lamp.

Step 2: Remove the dirt or dust particles on the lamp's surface using Optic Prep Pre-saturated Wipes. Avoid touching the lamp's surface to prevent contamination via fingerprint, and don’t re-use wipes as soil can scratch or contaminate.

Step 3: Use Coventry™ cleanroom swabs and Optic Prep Pre-saturated Wipes to clean the surfaces of the lens to remove dirt or dust particles. Don’t re-use swabs or wipes on these sensitive surfaces.

Step 4: Use the Chemtronics Aerosol Duster to obtain ultra-pure cleanliness of the lenses.

Step 5: Clean the overall body of the Optical system using Chemtronics dry wipes for final touches.

Step 6: Reinstall the Optical System, lamp, and return the cover.

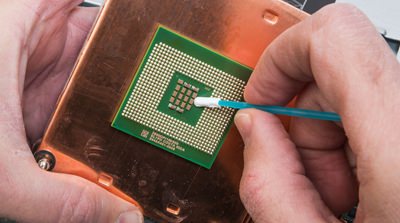

Cleaning the Cuvette

Step 1: Remove the cuvettes from the reaction disk or the flowcell.

Step 2: Place the cuvette onto an Optic Prep Pre-saturated Wipe and clean its surface using Optic Prep Pre-saturated Wipes and Coventry™ cleanroom swabs. These will remove excess oils or existing fingerprints. Don’t touch the cuvette surface; fingerprints and human-generated oils are some of the reasons for dirty cuvettes. Do not reuse swabs and wipes which could redeposit soil.

Step 3: Clean the reaction disk or the flowcell using Coventry™ cleanroom swabs, then reinstall the cuvettes in the system.

Overall External Cleaning

To ensure 100% cleanliness, we need to clean the overall machine. Using the Coventry cleanroom wipes & Chemtronics dry wipes, we can ensure 100% cleanliness and a dirt or dust-free workstation or laboratory.

What if you are the next patient to be tested and the laboratory machines are not well-maintained? Do you want to receive an incorrect diagnosis? That's why machine maintenance is a must but using the correct maintenance products is a plus.

Chemtronics Cleaners and Coventry Wipes & Swabs for Chemical Analyzer Maintenance

Chemtronics offers specialty cleaning products engineered to be effective and safe for the equipment, personnel and the overall environment.

- High precision solvent cleaners, either in aerosol or liquid form, are engineered to be safe on sensitive electronics and surfaces, but strong enough to remove flux, oils and other contamination.

- Lint-free wipes are strong and absorbent, and without risk of contamination from the wipe material itself.

- ESD-safe swabs are available in a wide variety of shapes and materials to clean inside the many tight crevices of lab equipment. The specialized handles prevent static build-up that can damage sensitive electronics

For more information, contact your Coventry cleanroom application specialist at 678-928-6534 or [email protected].